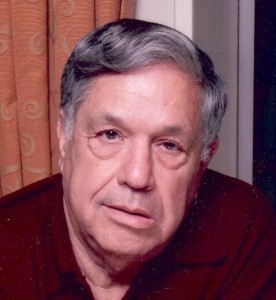

So said John Connolly, senior engineer at NASA and director of the Space Studies Program of the International Space University (ISU), which will come to the Technion this summer

When John Connolly lectures to children and young people he asks the audience, “Who was the first man on the moon?” – and the answer comes immediately: Neil Armstrong. When he asks who the second man on the moon was, the crowd falls silent, until Connolly discloses the first name “Buzz” and the young audience calls out in unison: “Lightyear!”

John Connolly, a senior figure in the aerospace industry, is rather pleased with the representation of space science in film and in art in general. He often advises movie producers, including the producers of the new movie, The Martian, and is well-versed in science fiction. “Ultimately, the way culture reflects reality in the field of space helps instill an awareness of the importance of NASA and other space agencies,” he says. “Movies, TV series and books assimilate space in the public consciousness, reflect the tremendous curiosity that drives us and present the challenges that we face in space.”

Of course, the popularity of space in movies also has its disadvantages. “Sometimes these movies do not place sufficient emphasis on the difficulty and the challenge. Sometimes people say to me: ‘Why invest so much in sending people to Mars? I recently saw a movie where it had already been done.’ Nevertheless, movies show the human side, especially the curiosity and the coping, and that is of great value.”

Connolly spent last week at the Technion in his capacity as director of the Space Studies Program of the International Space University (ISU), which has chosen the Technion as the site of its prestigious summer semester this year. He was accompanied by all the academic managers of the ISU, in order to plan the schedule of the program and visit the classrooms, dorms and all the other relevant sites.

Around 150 space experts will participate in the Space Studies Program (SSP) to be held this summer at the Technion, along with nearly 150 participants from academia and industry, astronauts and directors of space agencies from around the world. “We do not call them students because these are people with experience whose average age is 32,” says Connolly. The participants are carefully selected, based on the concept that they will be the space leaders of the future. Indeed, graduates of the International Space University’s program already hold senior positions throughout the global aerospace industry.

“Space is becoming more and more international,” Connolly explains. “Missions are bigger and more complex, like the International Space Station, for example, and require cooperation among agencies and among countries. That’s why the International Space University operates in a different place in the world each year – last year at Ohio University and this year (2016) in Israel, at the Technion.”

The intensive program that will take place at the Technion this summer will also include events open to the general public, including a robotics competition, rocket launches, space-related movie productions and a professional panel discussion about the Columbia space shuttle disaster. “We very much hope to bring Buzz Aldrin to the Technion. He was recently appointed Chancellor of ISU,” he says.

The program that will take place this summer at the Technion will mark the end of Connolly’s tenure as the head of the Space Studies Program at ISU, and he will return to NASA, which loaned him to run the SSP and the Southern Hemisphere Space Studies Program (SH-SSP) of the International Space University for a limited period.

Connolly came to NASA in 1987 as a young engineer after graduating from college, after working for a short time as a “plain old rocket scientist,” and since then he has gradually advanced within the organization. “As a boy I would often launch improvised rockets, draw spaceships and follow the Apollo missions, and an invitation to work at NASA was obviously an offer that I couldn’t refuse. It’s a great honor to make your dream come true and even get paid a salary. NASA people are paid the same salary as other government workers in the US, so you’ll never get rich, but I never considered giving up my job here. “

His current position at NASA is human space exploration engineer, which means the engineer responsible for planning robotic flights to Mars and the Moon, which are supposed to prepare the ground for future manned delegations. The non-manned delegations are supposed to test the environmental conditions (radiation, temperature, dust, etc.) and land the necessary equipment for the astronauts who will arrive in the future.

“There’s a lot more work to be done in this area, and that’s wonderful,” he says. “Humanity wants to go to Mars, and I’m glad to be part of this step. Maybe in the more distant future there will even be a permanent settlement on Mars – not because there’s no room on the planet Earth, but because man is a curious creature by nature. If you put a one-year-old baby on the floor, he’ll crawl to the low cabinets and will try to open them – because he’s curious. The same holds true for adults: mankind wants to find out what’s on the other side of the mountain, the other side of the sea, the other side of the ocean. And that’s the whole story with voyages into space – space is the next ocean that we want to cross in order to discover what’s just beyond our reach.”