Technion Researchers Win Prestigious Design Award for Developing New Technology to Protect Young Seedlings

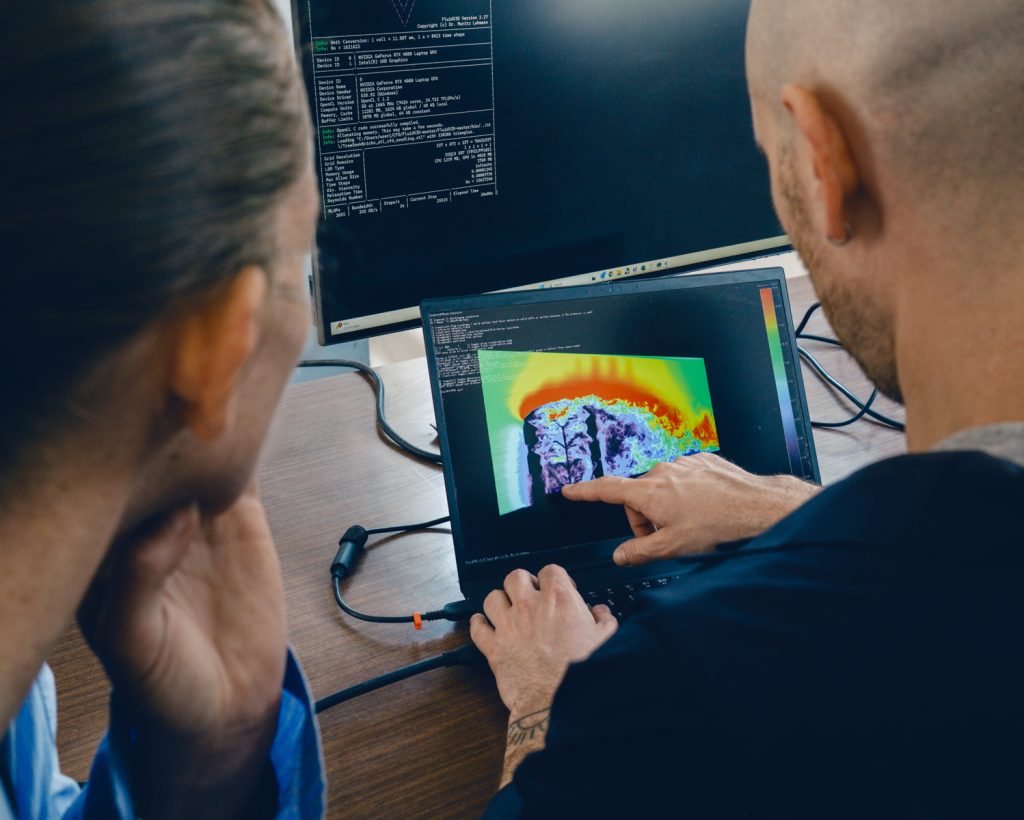

Doctoral student Ofer Asaf and Prof. Aaron Sprecher have developed a smart robotic printing method for shelters that protect young plants

A Technion project aimed at protecting young seedlings using robotic 3D printing has earned its developers the Red Dot Design Award, a prestigious international design prize, for the year 2025.

The project, TreeSoil, was led by doctoral student Ofer Asaf and Prof. Aaron Sprecher, head of the Material Topology Research Lab (MTRL) in the Faculty of Architecture and Town Planning. Also participating were Professor Emeritus Arnon Bentur from the Faculty of Civil and Environmental Engineering at the Technion and Prof. Tamir Klein, head of the Tree Lab at the Weizmann Institute of Science.

As part of the winning project, the researchers developed an innovative technology for robotic 3D printing using soil-based materials. The resulting structures serve to protect young seedlings, including in areas prone to erosion and landslides.

The TreeSoil structure creates around the seedling a microclimate that supports the early stages of growth by optimizing air flow, sunlight exposure, and humidity. It consists of modular blocks that make field installation easy. The printed material is based on local soil enriched with fertilizers and additives, tailored both to the specific environment and to the needs of the seedling. Since the materials are biodegradable, the structure naturally disintegrates as the tree matures.

According to Prof. Sprecher, beyond its specific application, the project offers a new role for architecture – one that includes ecological awareness, restoration, and the use of technology for environmental benefit. The project was supported by the Technion Center for Advanced Construction (TACC) and the Technion Sustainability Frontier.

Project page on the competition website – here

Video – here