“I Told My Father That the Technion Is My Place”

In honor of the International Day of Women and Girls in Science, meet Hiba Mallak, a Dean’s List honoree at the Henry and Marilyn Taub Faculty of Computer Science

In honor of the International Day of Women and Girls in Science, meet Hiba Mallak, a Dean’s List honoree at the Henry and Marilyn Taub Faculty of Computer Science

An innovative technology developed by Assistant Professor Ofer Berman of the Technion and researchers at Cornell Tech offers passive air cooling without electricity and without pollution

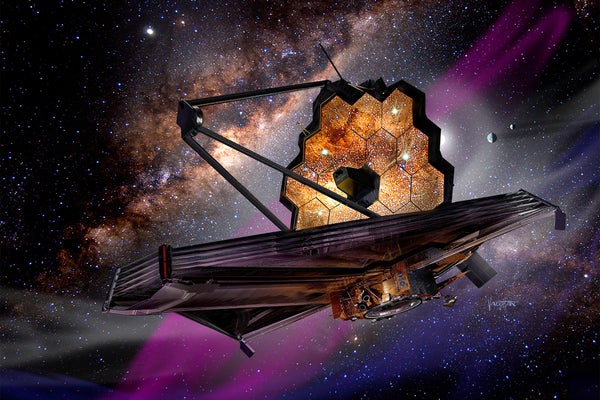

Technion-led team achieves first measurement of cosmic rays deep inside star-forming nebula 400 light-years from Earth

Technion on the Bar - When Waste Meets Recycling

17.02.2026 Tuesday, at 20:00

Add to calendar

The Second Israeli Conference on the Philosophy of Artificial Intelligence

04.03.2026 Wednesday, at 09:30

Add to calendar

Nature on Campus Photography Exhibition

04.01.2026 Sunday, at 09:00

Add to calendar

Landmarks Exhibition

01.01.2026 Thursday, at 09:00

Add to calendar

15000

Students

in a variety of degrees

60

Research Centers

across campus

18

Faculties

100000

Graduates