Towards Green Hydrogen

Decoupled water electrolysis paves the way for producing green hydrogen on an industrial scale – a breakthrough that would disrupt the global energy market and help combat climate change.

A recent review in Nature Reviews Clean Technology presents, for the first time, a pathway for scaling up decoupled water electrolysis (DWE) technologies to produce industrial-scale green hydrogen.

Hydrogen, a key chemical feedstock, is usually produced from fossil fuels, generating high CO₂ emissions. Water electrolysis powered by renewable energy emits oxygen rather than CO₂ and offers a clean alternative. Green hydrogen production on an industrial scale is one of the holy grails of the energy transition, as it would unlock the potential of replacing the world’s dependency on fossil fuels.

Conventional electrolysis uses two electrodes separated by a membrane to split water into hydrogen and oxygen. This approach is expensive, suffers from internal hydrogen leakage, and is incompatible with intermittent solar and wind power. DWE overcomes these issues by separating the hydrogen and oxygen production in time or space, eliminating the need for membranes. Rather, it uses redox materials that can absorb and release ions from which oxygen or hydrogen are produced.

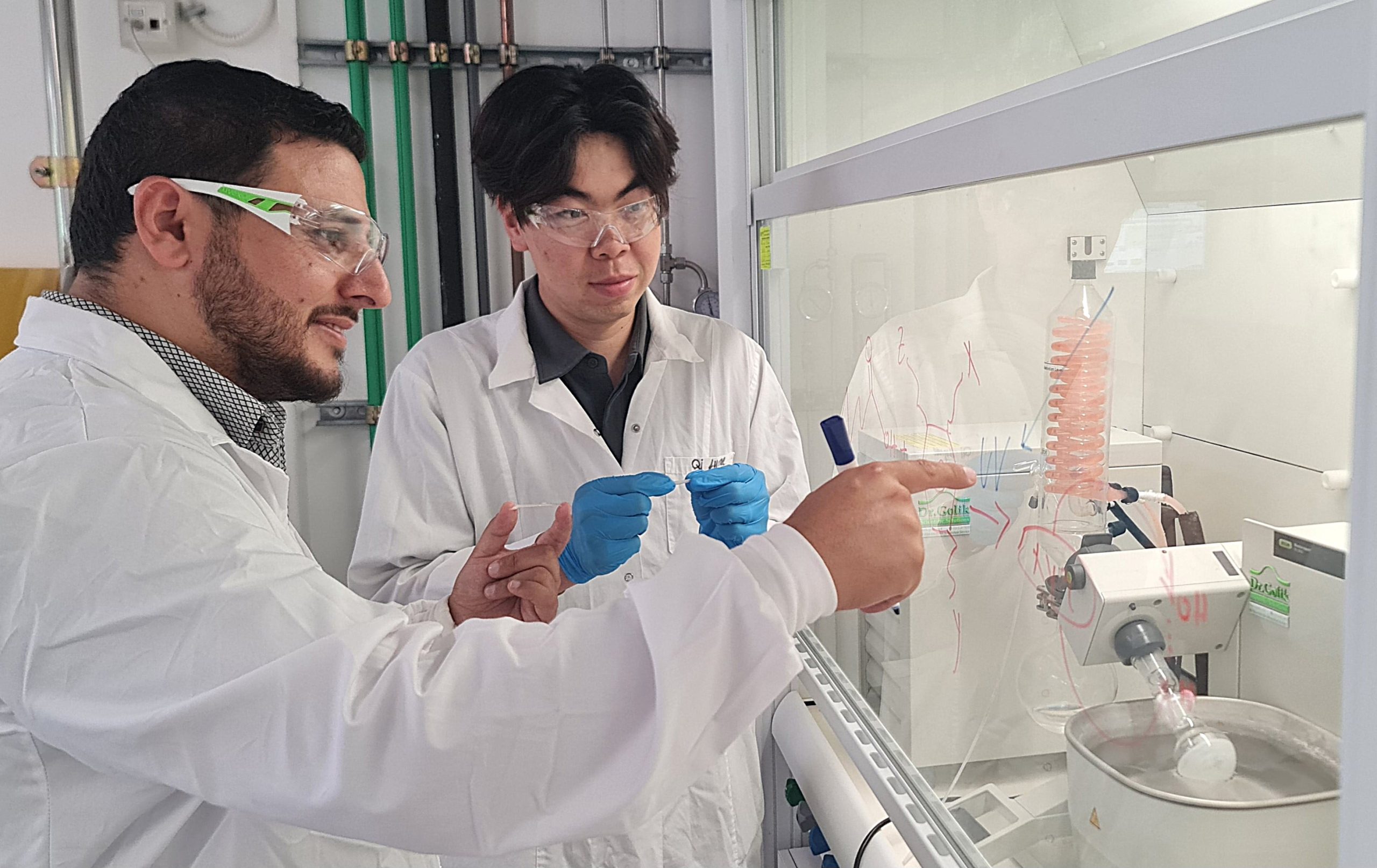

The article reviews different DWE methods and, for the first time, presents feasible scale-up pathways. The authors include leading experts from all over the world: Prof. Avner Rothschild of the Technion Faculty of Materials Science and Engineering, Prof. Mark D. Symes of the University of Glasgow, Prof. Jens Oluf Jensen of the Technical University of Denmark, Dr. Tom Smolinka of the Fraunhofer Institute for Solar Energy Systems ISE, Rotem Arad and Gilad Yogev from the company H2Pro, Technion postdoctoral fellow Dr. Guilin Ruan, and University of Glasgow doctoral student Fiona Todman.

Prof. Mark Symes and his collaborators at the University of Glasgow pioneered the original embodiment of decoupled electrolysis in 2013, using solution-phase redox mediators. He has continued his work on decoupled electrolysis using a variety of liquid-based systems and is actively trying to commercialize this technology through the company Clyde Hydrogen Systems.

In 2015, Prof. Avner Rothschild pioneered a new technology together with Technion colleagues Prof. Gideon Grader, Dr. Hen Dotan, and Dr. Avigail Landman, using nickel-based redox electrodes. Their breakthrough led to the founding of H2Pro in 2019. The company stands at the forefront of commercializing DWE. H2Pro’s patented technology entails a streamlined, membrane-less system, cost-effective materials, and low capital costs. H2Pro is currently scaling up this technology and preparing to install the world’s first DWE system. The system is ideally suited to cope with intermittent renewable energy sources such as solar and wind.

Prof. Jens Oluf Jensen and Dr. Tom Smolinka are world-renowned experts on state-of-the-art electrolyzer technologies. Their work in proton exchange membranes (PEM), anion exchange membranes (AEM), electrode materials, and their application in cell stacks for large capacity PEM and AEM electrolyzers provided valuable insight into the challenges of scale-up and operation of commercial electrolyzers, and a sound base for comparison of disruptive decoupled and membrane-less electrolyzer concepts. Rotem Arad and Gilad Yogev provide insights into transforming these concepts into technologies for green hydrogen production at scale.

This review is the first to detail feasible scale-up strategies for DWE. While lab-scale DWE experiments produce less than a gram of hydrogen per day, industrial systems must generate about a ton daily – a million times more! Indeed, meeting current hydrogen demand would require around a million full-scale electrolyzers. Conventional industrial electrolyzers, on the other hand, require a stable grid supply and can only be used to a limited extent with highly dynamic power fluctuations such as those caused by solar and wind energy.

DWE’s unique advantage lies in its energy storage capability via redox materials, functioning like an electrolyzer with a built-in battery. This allows it to buffer energy fluctuations from renewable sources, making it highly compatible with solar and wind systems, thereby offering a critical pathway to low-cost, green renewable hydrogen production.

The potential impact of scaling up green hydrogen production is huge. The hydrogen market is currently worth about $250 billion annually. Once it becomes available on an industrial scale, the market for green hydrogen is expected to reach $550 billion within ten years.

“Green hydrogen is expected to account for 10% of the future energy market. Once it becomes possible to produce green hydrogen at large-scale and sell it at reasonable prices, hydrogen will replace a large part of the energy used in industry, heavy transportation, and other sectors,” Prof. Rothschild predicted. “Traditional electrolyzers should evolve to fit this market and, as noted by Darwin, it is not the strongest species that survives through evolution but, rather, the one that is best able to adapt and adjust to the changing environment in which it finds itself. I believe DWE would be it.”

“Decoupled electrolysis is only about 12 years old. More conventional technologies, such as alkaline and proton-exchange membrane cells, have had decades (if not centuries) for development. This gives some context to the rate of scaling of some of the new decoupled systems starting to emerge,” elaborated Prof. Symes. “On the current trajectory, I expect that the next decade will see decoupled electrolysis systems becoming serious competitors to more conventional electrolyzers, especially for the conversion of renewable energy to green hydrogen.”

The new ideas presented in the review article are compelling and shed light on the long-term prospects of scaling up DWE technologies for the benefit of all humanity.