Cultured Hamburgers Coming Right Up

Cultured meat platform developed through the structuring of edible scaffolds with oil gel-based fat substitute

Cultured meat, the lab production of meat from isolated farm animal cells using tissue engineering techniques, is considered an alternative to meat, thus providing meat-like products with similar eating experience and nutritional values to animal-derived meat. Aiming for a low environmental impact and enhanced animal welfare, this alternative not only offers an available protein source for the world’s growing population, but also a more humane and sustainable one.

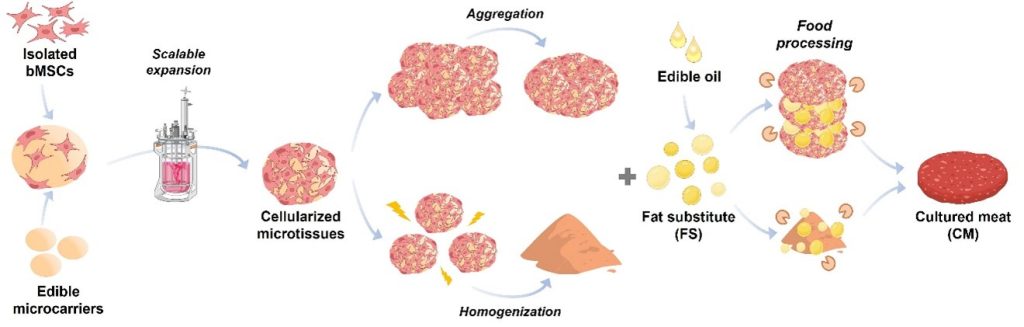

In the collaborative research by Prof. Machluf, Prof Fishman, and Prof. Davidovich-Pinhas from the Faculty of Biotechnology and Food Engineering at the Technion – Israel Institute of Technology, the researchers address some of the major technological challenges facing the cultured meat field: the development of technical solutions for scalable cell expansion, cell scaffolding, and cell-to-meat processing. The researchers introduced a new approach for the development of diverse cultured meat products, based on edible vegetable-based scaffolds in combination with vegetable-oil gel (oleogel) fat substitute. In this approach, cell expansion is carried out using microcarriers, which act as scaffolds for cell attachment and proliferation, thus enabling a scalable process in bioreactors. Since the microcarriers were designed from edible materials, they can be directly incorporated into the final cultured meat product without requiring any costly cell harvesting steps.

Another essential building block of cultured meat is a fat substitute, which contributes to its tenderness and juiciness as well as to the overall taste. To this end, a vegetable-oil gel fat substitute was developed and incorporated with plant protein. The novel formulation exhibited comparable appearance, color, and hardness to beef fat, with better nutritional values. Furthermore, due to its protein shell, the fat substitute could be easily combined with the protein-rich microtissues into a coherent structure.

Schematic illustration of the cultured meat platform. Edible microcarrier-derived microtissues are first produced in a scalable bioreactor and then undergo processing such as aggregation or homogenization. The processed cellular mass is further incorporated with an oleogel-based fat substitute followed by food processing methodologies to generate cultured meat prototypes. Created with BioRender.com.

Two types of cultured meat prototypes are described in the paper: layered cultured meat and burger-like cultured meat. The layered cultured meat prototype was produced based on microtissue aggregates that supported better stiffness and nutritional values, while the burger-like cultured meat utilized homogenized microtissues to imitate the marbling appearance of animal-derived meat.

Altogether, taking a multidisciplinary approach, this work establishes the technological basis for a unique cultured meat platform that may broaden the applicability of cultured meat products and accelerate their commercial production.

The study was conducted by postdoctoral fellows Dr. Jovana Glusac and PhD student Feng-Chun Yen. Additional contributors included Dr. Anton Zernov, senior research fellow Dr. Limor Baruch, and PhD student Shira Galperin-Levi from the lab of Prof. Machluf. The research was funded by GFI – The Good Food Institute.