Fabricating Advanced Membranes

Membranes developed by Technion scientists and their German colleagues enable precise selective separation of nanoparticles

Researchers from the Technion – Israel Institute of Technology and the Helmholtz-Zentrum Hereon Center in Germany have developed a new concept for fabricating membranes for on-demand nanoparticle separation with high selectivity. These membranes are relevant for diverse applications that include pharmaceutical processing, materials separation, water purification, and wastewater treatment.

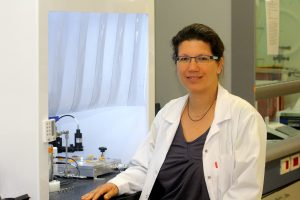

Published in Advanced Materials, the research study was led by Assistant Professor Tamar Segal-Peretz and Ph.D. student Assaf Simon of the Wolfson Faculty of Chemical Engineering at the Technion, together with Dr. Zhenzhen Zhang and Professor Volker Abetz of the Helmholtz-Zentrum Hereon Research Center.

High-selectivity molecular separation is a common process in nature that occurs, for example, in cell membrane channels. Membrane channels separate the interior of the cell from its outside environment and regulate which materials can pass into and out of the cell. Inspired by nature, numerous research groups have attempted to develop similar membrane channels that enable precise filtration of various materials for diverse industrial applications. But synthetic fabrication of such membranes, with high levels of well-ordered pores, and high uniformity and selectivity, poses a complex engineering challenge, made even more complex when the membranes are intended for extremely small nanoparticle separation.

Right: Membrane manufacturing process – growth of metals within the membrane channels in a precise way that controls their size, and then creating a response to obtain a membrane with a unique physical property. Left: Sectional view of the membrane showing a combination of the metal oxides on top of the block-copolymer membranes.

The Technion and Helmholtz-Zentrum Hereon researchers succeeded in fabricating such membranes using block copolymers – spontaneously self-assembled polymer molecules, in combination with metal oxide growth on and within the block copolymer pores. The process developed by the researchers provides an excellent method for precisely tuning the pore size as well as other properties of the membrane. In addition, the metal oxide is an ideal base for incorporating functional groups on the membrane surface, granting it unique properties, such as electric charge and hydrophobicity (water repellency). These membranes exhibited superior performance in the separation of nanoparticles based on size, charge, and/or hydrophobicity.

Prof. Segal-Peretz estimates the breakthrough will provide various industries with a new, versatile, and accurate tool for the filtration of molecules, pollutants, and other particles.

Click here for the paper in Advanced Materials.