Physical Review Letters reports: Technion researchers discover a new mechanism for contact formation between crystalline nanoparticles in nanopowders

Nanopowders are the basis of many nanotechnologies; Technion researchers coin a new term in the field of nanomechanics: “pseudo-elasticity”

Nanopowders are the basis of many nanotechnologies; Technion researchers coin a new term in the field of nanomechanics: “pseudo-elasticity”

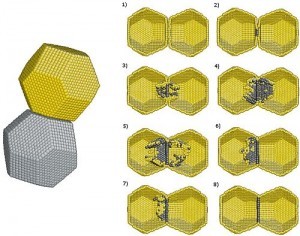

“In the scientific world today, there are two central schools of thought regarding the way nanocrystals come into contact,” says Prof. Eugene Rabkin of the Faculty of Materials Engineering at the Technion. “One school asserts that the crystals homogenously stretch in order to stick together (elastic deformation), but once they adhere, they return to their original shape. According to the other school of thought, as they approach, the inter-atom forces are strong enough to overcome the individual nanocrystals’ strength and compel them to change shape irreversibly (plastic deformation).”

Metallic nanocrystals have an orderly atomic structure, and the way in which they can undergo plastic deformation is by creating a linear “defect” in the orderly atomic structure. These linear defects, which are called “dislocations”, were first observed under a microscope in the mid-1950s and since then they have served as an important basis for understanding the mechanical characteristics of materials. Because of the size of nanocrystals, they generally have a perfect atomic structure and do not have dislocations.

“Justification for both schools of thought has been offered, yet without a way to resolve the contradiction between them,” adds Prof. Rabkin. “On the one hand, analytical models have shown that the stresses that are created in nanocrystals during the contact formation are large enough to create a large number of dislocations; on the other hand, in experimental observations, only isolated dislocations were observed in the nanocrystalline clusters, in contradiction to the models.”

In order to resolve the contradiction, the Technion researchers used advanced simulation tools that run on high-performance parallel computer located on campus. “The calculation is performed at the atomic level,” relates Dr. Dan Mordehai who today is a member of the Faculty of Mechanical Engineering at the Technion, but who was a post-doctoral fellow in Prof. Rabkin’s group when the research was conducted. “We describe the nanocrystals using the atoms that comprise them and the forces between these atoms, and thus, we actually allow the atoms to choose their preferred “path”. These calculations include several hundreds of thousands of atoms and we have to execute them on parallel computer – that is, execute the calculation on a number of computers simultaneously.”

The Technion researchers found, for all intents and purposes, that neither of the schools of thought described the process in its entirety. In their simulation they showed that when the nanocrystals approach each other, the force of their interaction rises to become as great as that which creates many dislocations (as predicted by the second school of thought). Nevertheless, during the adhering process between the nanocrystals, additional dislocations are created, which “repair” the defects, and by the end of the adhering process, they no longer have any dislocations, as observed during experiments.

Thus the new nanomechanical term, coined by the Technion researchers, “pseudo-elasticity” was born. This mechanism enables nanocrystals to retain their original shape, despite the forces acting upon them, which are large enough to overcome their own strength limit. This mechanism may have great importance in many additional fields in contact mechanics for each pair of bodies that gets within a few nanometers of each other.

Prof. David Srolovitz, who is the head of the Institute of High Performance Computing in Singapore, participated in this research.

Above: Pictures of the simulations that were performed in the Technion show the process of contact formation between two nanocrystals. (Left) The atomic structure of nanocrystals before contact. (Right) The pseudo-elastic mechanism in action (1 to 8). In order to demonstrate the mechanism, only some of the atoms necessary for the process are shown. One can see that during the process of adhering, many defects are created (the atoms appear in dark grey in pictures 3-7), but at the end, the nanocrystals do not exhibit any defects (8). Illustration: Technion Spokesman.